Applications

Heat Trace Cable & Wire Securing Tape - Thermal Insulation Sleeve / Tape / Wrap

Heat Trace Securing Tape & Thermal Insulation - high temperature up to 500°F / 260°C continuous

Heat Trace cables and wires on pipes and hoses can be secured and thermally insulated with a variety of sleeve, tape and wrap products.

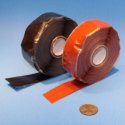

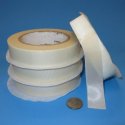

Firstly, the heat trace cable/wire can be secured to the hose or pipe with heat trace securing tape. Both types of securing tape provide excellent high temperature performance. The silicone securing tape has no adhesive and secures the heat trace cable or wire by self-amalgamating or fusing to itself along the tape's overwrap area. Easy to install and easy to remove with no sticky residue or adhesive. The fiberglass tape with silicone adhesive is reinforced to provide excellent strength and hold at high temperature.

Alternatively, stainless free-end, self locking band clamps can be used to secure the heat trace cable or wire to the hose or pipe.

Once the heat trace cable/wire has been secured to the hose/pipe, then various types of insulation can be applied. Knit or Woven insulation sleeves which can be slid over the pipe/hose, knit or woven tapes which can be spirally wrapped down the length of the pipe/hose, or insulated pipe wrap tape with velcro closure can be longitudinally attached or spirally wrapped.

Other silicone coated sleeve, sleeve with velcro, sleeve with zipper and sleeve with snap closure can also be used.

Enhanced protection can be achieved by first using a base layer of white colored knit or woven sleeve or the knit or woven tape, and then adding the coated protection sleeve over the base sleeve.

Sleeves and tapes can be multi-layered - multiple base sleeves and multiple outer sleeves.

Knitted sleeves are very self conforming and have minimal radial elasticity, and hold themselves to the pipe or hose when correctly sized. Braided sleeves have good radial elasticity, but must generally be pulled tight and secured to hold close to the pipe or hose. Both have advantages and disadvantages during installation.

Knitted tapes are very conformable when spiral wrapping pipes and hoses, while woven tapes are stiffer and provide a denser insulation coverage.

We can also fabricate custom fitted removable covers with built-in heat trace.

How thick an insulation layer you need and what amount of heating you need we can calculate based on computer modeling - please contact us with the details of your application so we can recommend the appropriate solution. The information you will need is 1) The ambient temperature range, 2) size of the pipe/hose, 3) temperature of the liquid or gas inside the pipe/hose, 4) flow rate of the pipe/hose, 5) Desired temperature of the liquid or gas inside the pipe/hose.