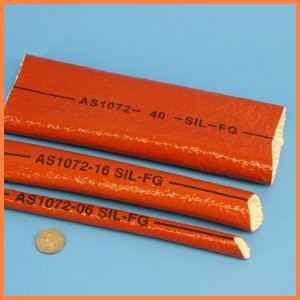

Products > FIRESLEEVE GROUP

SAE AS1072E Aviation Firesleeve for Wire, Cable and Hose Protection from high temperature, heat, flame & fire

Allows qualified hose assemblies to pass AS1055D

500°F / 260°C Continuous Exposure / 1000°F / 537°C Peak Exposure

FlameShieldTM aviation / aerospace grade high temperature, heat, flame and pyro resistant firesleeve jacket is manufactured to SAE AS1072E standards so it can pass the fire testing standards of AS1055D; and the requirements of FAA TSO - C53a and TSO - C75.

It may be used for all fuel, oil, hydraulic, fire extinguisher and prop feathering lines. "Fire-proof" hose lines, as defined by the FAA, must withstand a direct flame for fifteen minutes under specified flow conditions without failure. Fire-resistant lines must withstand a 5 minute exposure under these conditions.

Fire-proof hose lines are obtained when the proper size Firesleeve is selected and properly assembled with appropriate clamps.

Firesleeve is available in sizes ranging from 0.25" Inside Diameter through 5" I.D. in 25 size steps.